| NO. | Property | Description |

| 1 | Brand/Origin Place | Safebuild/Shandong China |

| 2 | Product Name | Highway Guardrail Crash Cushion Barrier |

| 3 | Material | Steel Grade Q235,Q345,S235JR,S275JR,S355JR,EN10025,A283M |

| 4 | Grade Strength | TS/TA/TB |

| 5 | Size | 5360*1050*860mm/3910*1050*860mm/2470*1050*960mm/2650*1100*900mm or Customized |

| 6 | Surface Treatment | Hot-dip galvanized and galvanized plastic spraying coating |

| 7 | Feature | Great Corrosion Resistant, High Intensity, Durable |

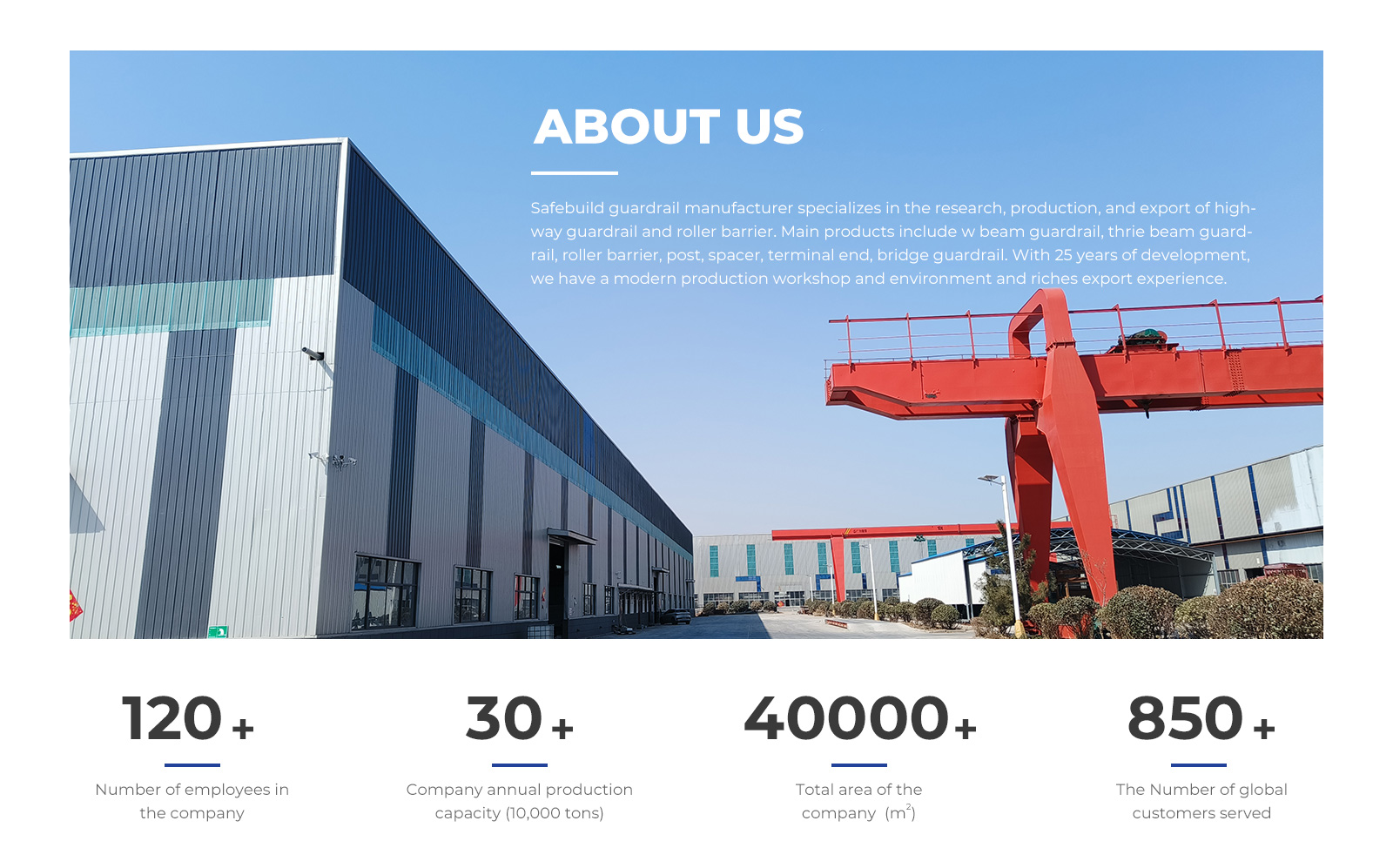

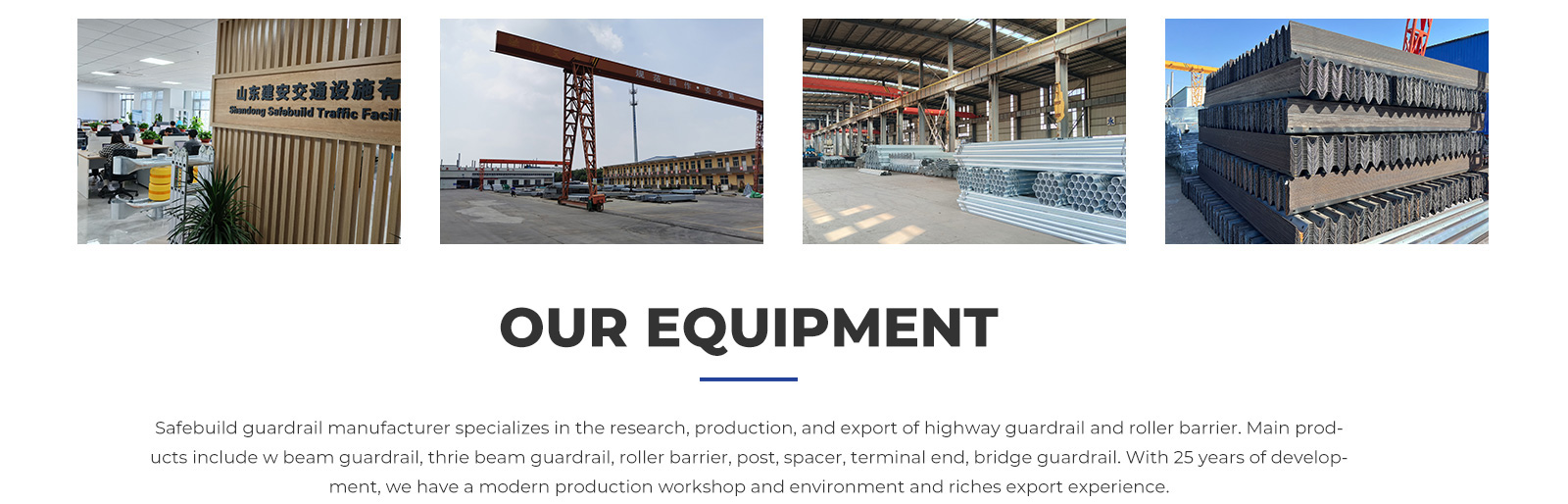

Safebuild is the source factory specializing in traffic guardrail with 25 years production and export experience. Due to our partnership with global brands, we understand the importance of your quality and you need more than a supplier. With Safebuild, the national leader in highway guardrails and Roller Barriers.

Anti-collision cushion is a device that can stop the vehicle safely and change the driving direction of the vehicle to avoid serious injuries to passengers by absorbing the collision energy of the vehicle. Its main function is to reduce the severity of the accident. On the other hand, it also plays a warning and inducing role through its surface color and graphic symbols.

An anti-collision pad is another name for an anti-collision block, buffer pad, rubber block, etc.The cushion is mainly installed at the edge of the loading and unloading platform, which facilitates the parking of trucks and reduces the difficulty of parking for drivers. It plays a role in protecting the platform, loading and unloading equipment of the platform and trucks from damage.

Anti-collision adhesive is one of the necessary protective devices for unloading platform.Craps made of material and process rubber are usually applied to the entire front edge of the cargo platform, while crAPS made of natural rubber (the same material as automobile tires) are usually used to fix both sides of the loading and unloading position equipment.

Highway Guardrail Crash Cushion Barrier | |

Steel Material | Q235,Q345,S235JR,S275JR,S355JR,EN10025,A283M |

Grade | TS/TA/TB |

Weight | 1100/700/500kg |

Size | 5360*1050*860mm/3910*1050*860mm/2470*1050*960mm/2650*1100*900mm or Customized |

Standards | JT/T2811995/AASHTO M180/RAL RG620/AS NZS/BS EN1317 |

Surface treatment | Hot-dip galvanized and galvanized plastic spraying coating |

Zinc Coating | 300g/m2 (40um),/550g/m2 (80um) ,610g/m2 (85um),1100 g/m2 (160um),1220 g/m2 (170um) or Customized |

Post Feature | Great Corrosion Resistant, High Intensity, Durable |

Kinetic energy principle anti-collision pad is generally composed of the end, energy absorbing material, both sides of the beam,diaphragm and back support. After a vehicle collides with the anti-collision pad, it absorbs the energy of the colliding vehicle through the deformation of the end part and energy absorbing material, and the back support is used to resist the impact force of the vehicle.

Energy absorbing material is generally foam material or rubber material, the principle of the anti-collision pad for the front and side of the vehicle has a good effect of energy absorption and guidance, and the system after the collision, the main components can be reused, convenient and fast maintenance and low cost, the disadvantage is a little more complex and high cost of the initial installation.

The principle of momentum conservation is generally composed of sand filling or water filling anti-collision cylinders (piers) of different masses arranged in a certain order. After a vehicle colliding with the anti-collision cushion, the momentum of the vehicle is transferred to the anti-collision cylinder in turn, which reduces the speed of the vehicle and the anti-collision cylinder in turn, and finally makes the speed of the vehicle lower than 15km/h.

It has a guiding anti-collision cushion structure with the protection level reaching TS, TA and TB, and its safety performance meets the requirements of the Highway Guardrail Safety Performance Evaluation Standard (JTG B05-01 -- 2013).

It can be applied to the main diversion terminal, ramp diversion terminal, tunnel entrance, middle pier end of the bridge, tollisland, front end of special obstacles and upstream end of some roadside guardrail, etc.The guide cushion and guardrail standard section have smooth transition connection, which meets the requirements of standard specification.

It has an efficient stage-by-stage buffering and energy-absorbing structure, which has been verified by the collision test of real cars. It has a large safety reserve and high safety performance.Modular design, easy to install, energy absorption components can be partially replaced, low maintenance cost.

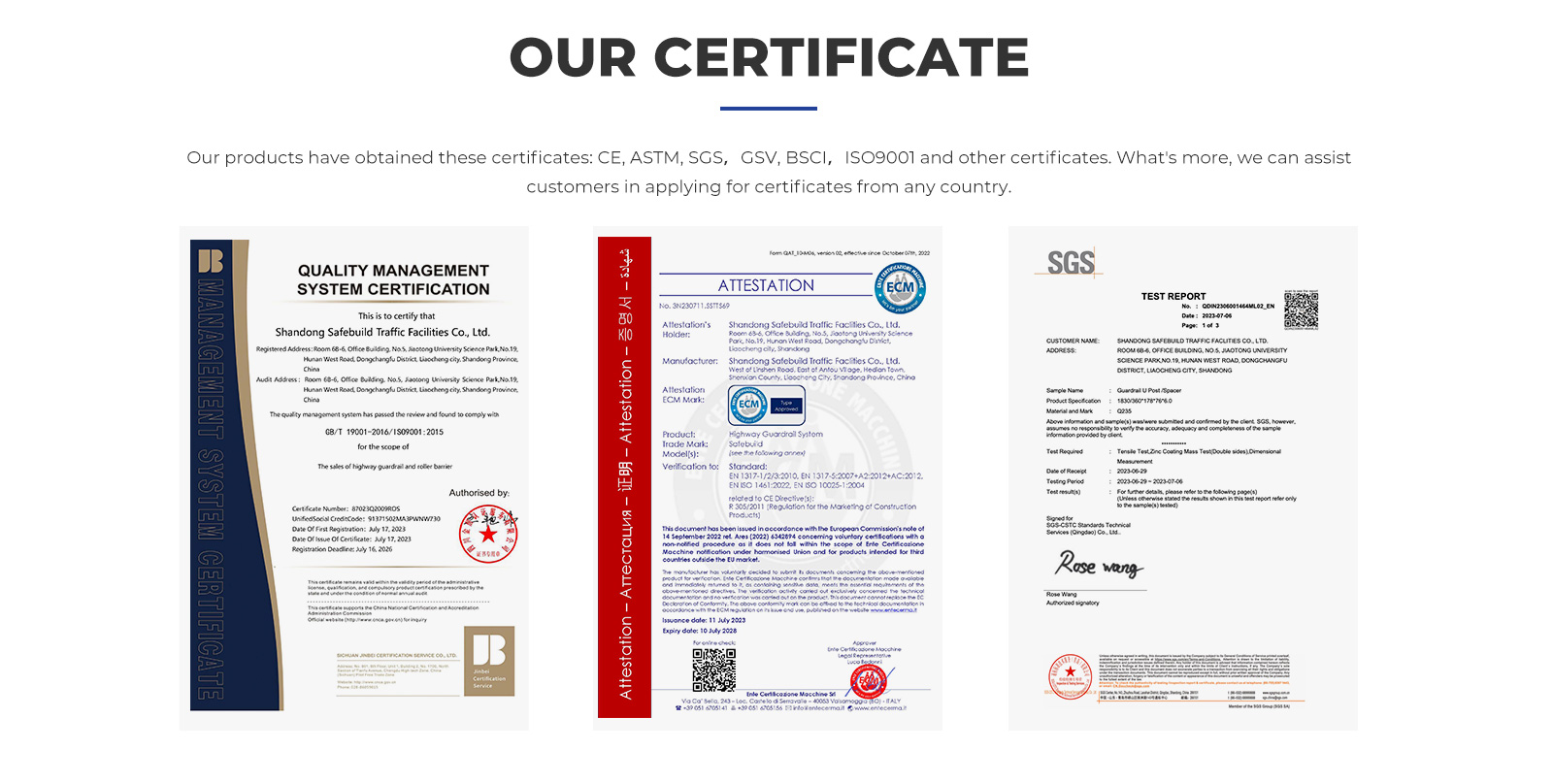

As a professional manufacturer of highway guardrail , all of our products are with CE, ASTM, SGS, GSV, BSCI and ISO9001 Certificate and keeps updating regularly to ensure product quality and production safety.

01 High quality steel materials

Safebuild use prime steel in each guardrail design.The advanced technology isuniform and smooth, without stripping rust,and the impact of collision has reached thetraffic sector standard.

02 Strong customization capability

With a R&D team of 12 people with more than 10 years experience, our factory provides from design, mold opening to production. So far, we have provided OEM and ODM services to more than 120 customers.

03 Strict quality control system

6 QC employees and 15 steps quality checking ensure our highway guardrail 100% reaching the standards of safety. Galvanized guardrail plate, not raised and cracking, the saline spray test does not have corrosion,the phenomenon of inflated and fall off without folds after high and low temperature, strong resistance to impact resistance.

04 Professional export services

We have more than 25 years of export experience in technology research and development, quality control, packaging and shipping and other links to provide professional advice and service.